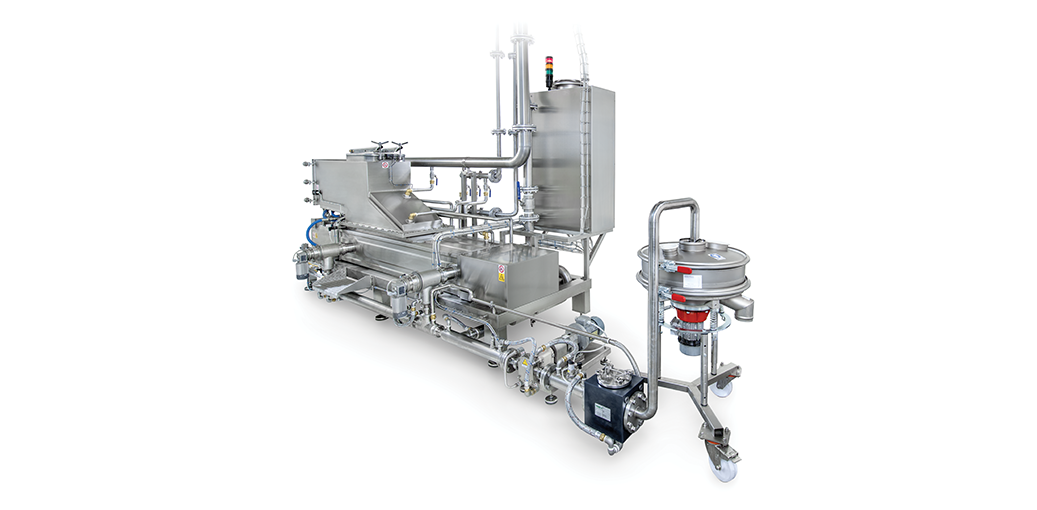

Continuous melters for cocoa and chocolate mass

The TECNO 3, FC-C continuous melter is intended for the confectionery factories that process cocoa and chocolate mass in blocks.

It is equipped with a special innovative system that guarantees high productivity, a reduction of energy costs and labour savings. The efficiency of the heat exchange is excellent, as a result of the mechanical work of hot rotors, which operate a scraping action on the blocks surface.

Cocoa and chocolate mass blocks are easy to be fed, with no need to lift them, as the loading hopper is placed at operator height. The loading surface, tilted and hot, makes them easily slide towards the rotors, which are heated and fitted with a thin spiral; tha latter acts as a scraper and constantly creates a new area to melt in contact with the hot part. The melted product is collected in a tank where the rotors are installed and is constantly collected and sent to the next production step. Before the transfer pump, there is a filter to catch any foreign bodies.

The melting cycle is considerably reduced compared to classic static systems, without the use of too high temperatures, thus allowing to keep the organoleptic properties of the raw material unaltered.

Thanks to the small footprint, the continuous melters can be installed even in small spaces.

Entirely made of AISI 304 stainless steel and perfectly insulated, the FC-C continuous melters are equipped with a double thermoregulation circuit, to keep the operating temperature constant and controlled, and managed by a complete electrical system integrated into the machine.

TECNO 3, continuous melters can be equipped with automatic devices for the total emptying in case of product changeover and optionally with CIP cleaning system.