MIO

Batch mixing chocolate and fat creams

Robust

compact

homogeneous

fast

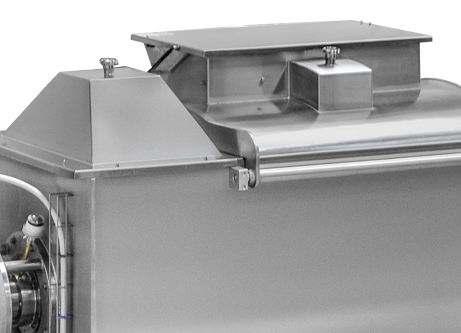

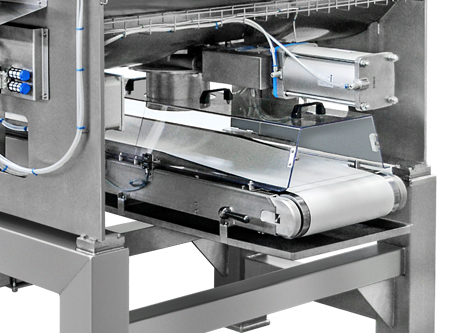

The MIO series horizontal mixers are designed for batch preparation of mixtures of liquid and solid products. They can be mounted on loading cells to accurately dose the ingredients. These are introduced in the upper part of the tank either manually or automatically. The stirring shaft is fitted with paddles oriented in a particular layout, which allow homogeneous mixing in the working phase as well as complete evacuation through the outfeed mouth, fitted with guillotine valve.

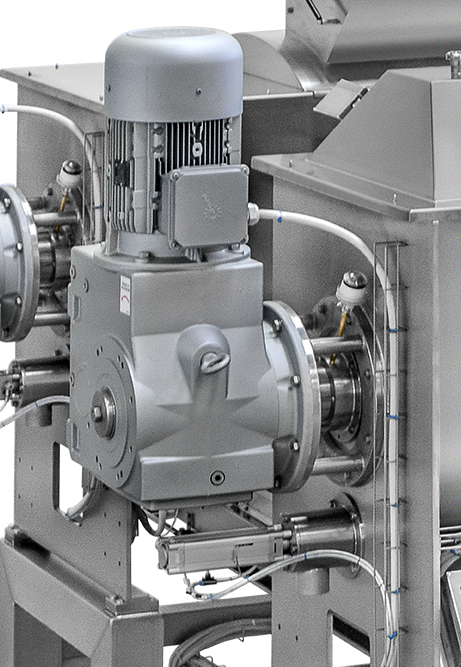

The machine body is thermostatically controlled with water circulation in the cavity, complete with insulation. The machine is made entirely of Aisi 304 stainless steel, complying with health regulations, with a very robust structure, capable of kneading particularly viscous mixtures. The kneading mixer can be equipped with an automatic washing device for the mixing chamber for recipe changes.

There is the possibility to automate ingredient feeding and dosing, mixing and unloading operations, and all parameters can be set on a PLC-controlled touch-screen operator panel.

What you can produce

Semi-finished products for the ice cream and confectionery industry

Flavoured or coloured products

Products with solid inclusions or powders

With the MIO series horizontal kneading mixer you can batch mix liquid and solid products homogeneously

What are the characteristics

Automatic loading of ingredients takes place safely with the agitator in motion and dosing is managed by PLC

Extensive management of dedicated recipes, which can be stored on a PLC with the possibility of transfer to company networks

In manual mode, the operator panel is equipped with a recipe control and management system that indicates the sequence, quantity and dosage of ingredients to be inserted, using a barcode reader

Recipe control and management system in manual mode with dosage indication and ingredient sequence via operator panel

Manual loading of ingredients takes place safely with the agitator in motion, thanks to an upper loading door with the possibility of checks/small additions via a porthole

Possibility of incorporating several machines in the line to achieve a continuous production process

Reduced energy consumption

Excellent mixing homogeneity

Ability to process dense and viscous products

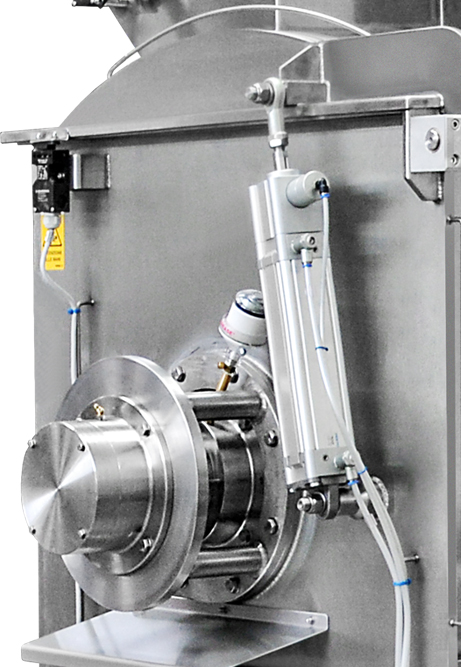

Adjustable guillotine outlet opening for different product viscosities

Cleaning the mixing chamber is facilitated with the use of the automatic washing device

Integrated predictive maintenance monitoring and reporting system with remote control capability

Related products