Traditional static melting

Efficient

compact

simple

robust

The FS1 series static melter is designed to melt fat blocks, anhydrous butter and hydrated fat (vegetable fat, diary butter, etc.), cocoa mass, chocolate and surrogate. It is intended for the confectionery, dairy and food industries in general.

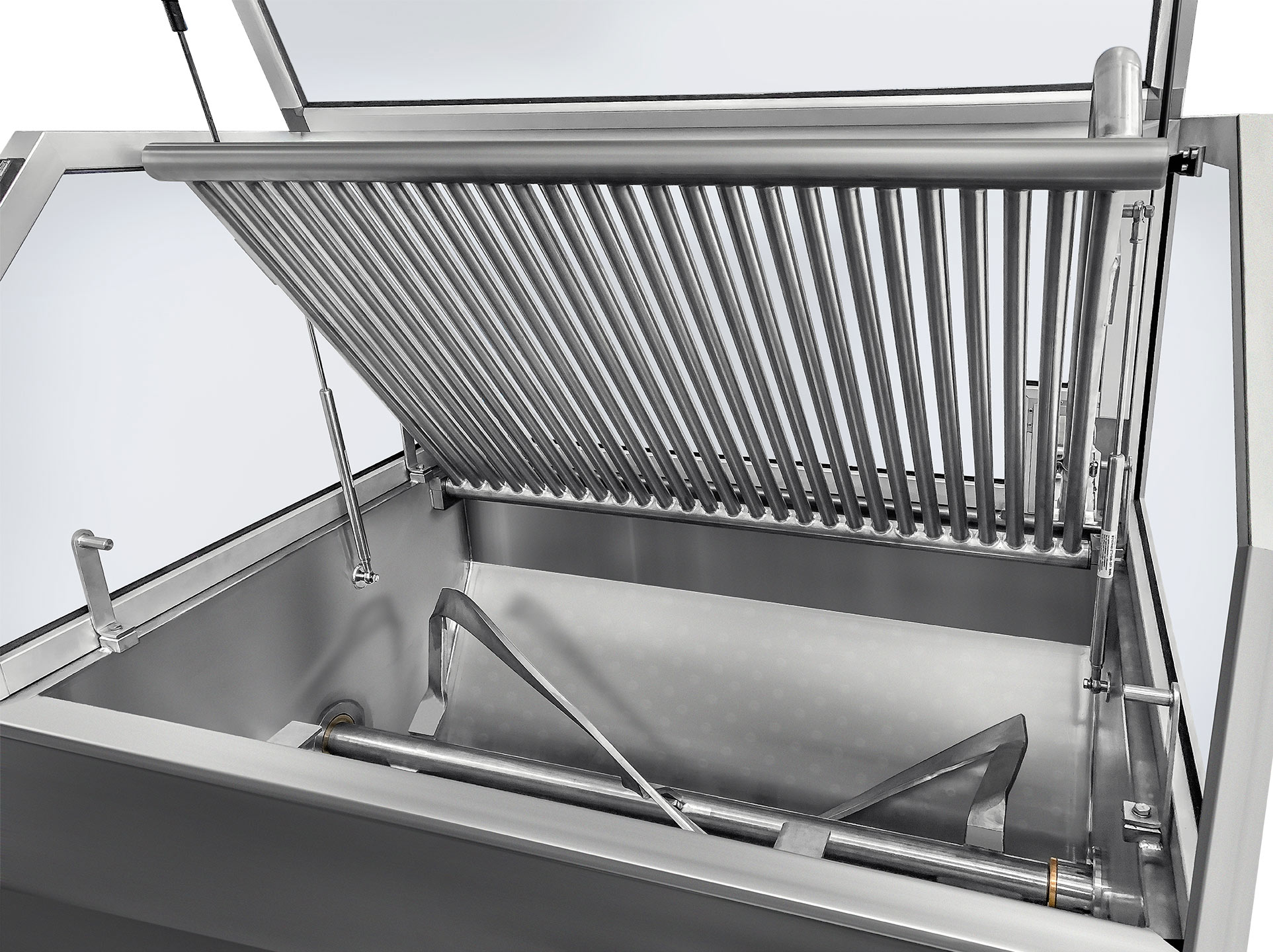

The FS1 series static melter consists of a melting chamber inside which there is a heated tank containing the melted product and a fusion grid, positioned on top of the tank, in which two flows of hot water circulate at set temperatures and different from each other. The double temperature control circuit is controlled by a PLC to keep operating temperatures and melting parameters controlled and constant.

The blocks of fat are placed in the melting chamber above the hot grid, the part in contact melts rapidly and drops into the tank below, the small sheets of product still solid that pass over the grid complete their melting inside the containment tank.

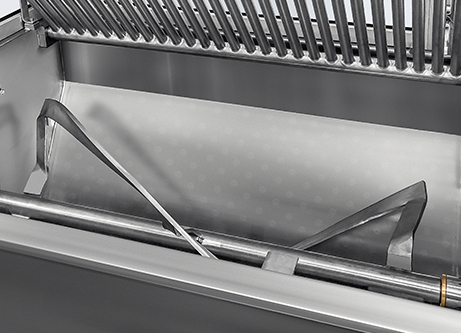

The FS1 series static melter is equipped with a agitator inside the cradle-type melting tank to prevent any separation of the ingredients in the case of hydrated fat (diary butter and vegetable fat) and to increase the speed of the melting process in the case of all other anhydrous products.

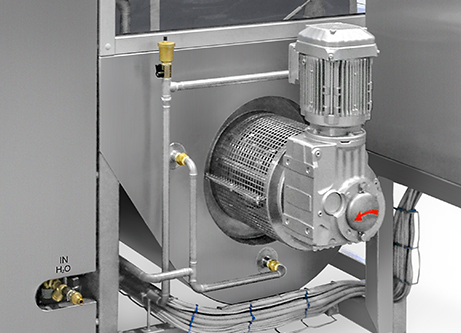

The control PLC also manages the product transfer pump, which can be fitted with a measuring device to dose the amounts. Before the transfer pump there is a dual action filtering system to catch any unwanted substances and a neodymium systems intercepts further metal impurities.

The FS1 series static melter is equipped with a dust-proof top cover and all parts are easily accessible for cleaning and maintenance operations. The hinged fusion grid allows access to the bottom of the tank.