Melting large blocks

Efficient

compact

robust

fast

modular

The FGB series static melter has been specially designed to melt cocoa mass, chocolate, compounds, cocoa butter and fats in large blocks weighing up to 1000 kg each, with the possibility of melting up to 4 blocks side by side at the same time. It is intended for the confectionery and food industries.

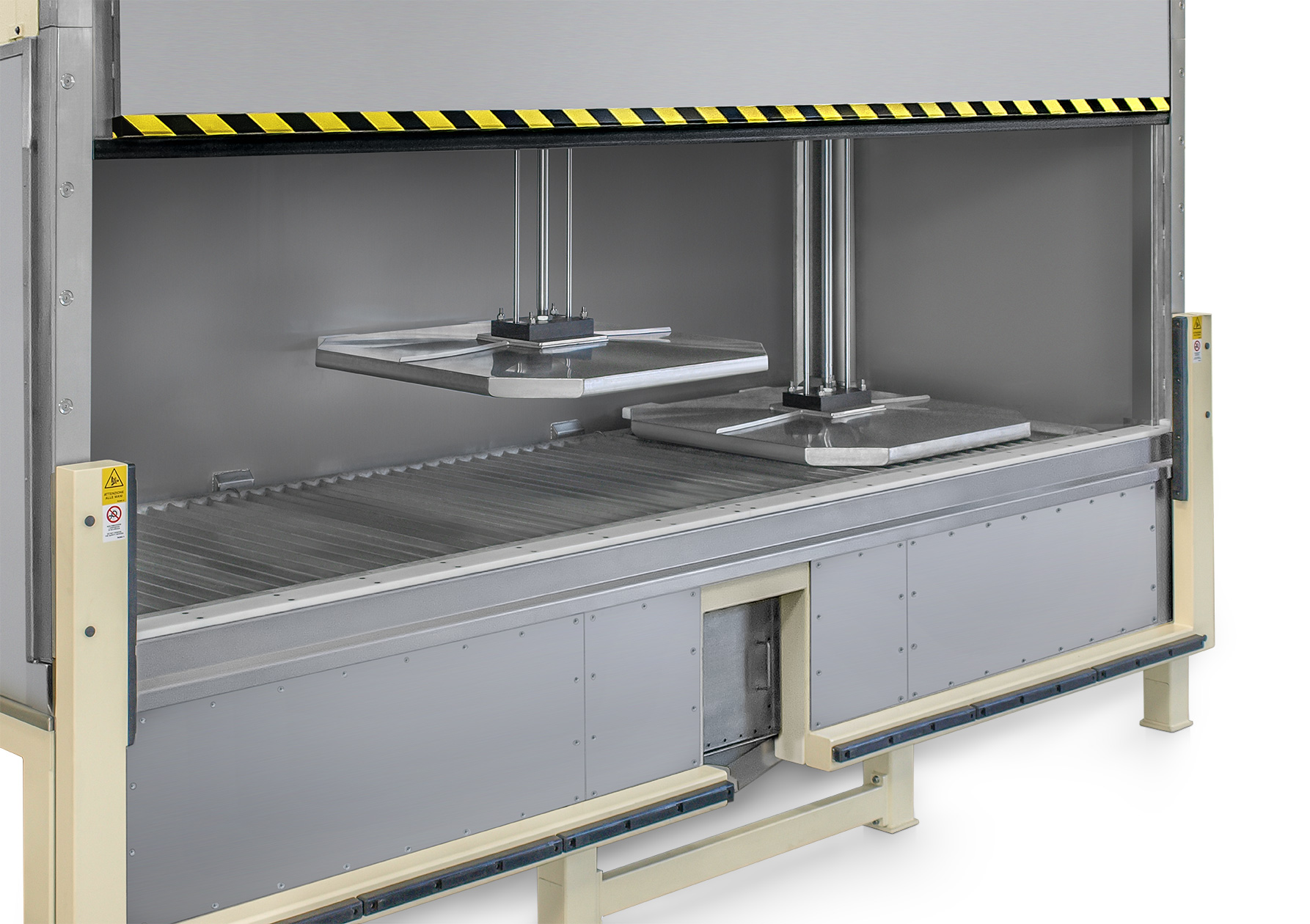

The system consists of a melting chamber, closed by a sliding door, inside which there is a heated tank containing the melted product and a fusion grid, positioned on top of the tank, in which two flows of hot water circulate at set temperatures and different from each other. The block is inserted into the melting chamber above the hot grid by means of special elevators, the part in contact melts rapidly and descends into the tank below, the small flakes of product still solid that pass over the grid complete their melting inside the melting tank.

A pneumatic presser pushes the block to be melted against the melting grid, which penetrates the mass more easily, thus accelerating the process. The melting cycle starts automatically when the door is closed, with the descent of the pneumatic presser, and ends when the same presser reaches the end of its stroke, warning the operator with an acoustic signal. Before the melted product transfer pump there is a double filtering system to catch any unwanted substances. Subsequently, a neodymium systems intercepts further metal impurities.

The melters vary in capacity and size according to production requirements, starting with one block at a time to be melted, up to a maximum of 4 blocks being processed simultaneously.

The FGB series static melters are equipped with a dual PLC-controlled temperature control circuit to keep the operating temperature controlled and constant.