Heated portable tanks

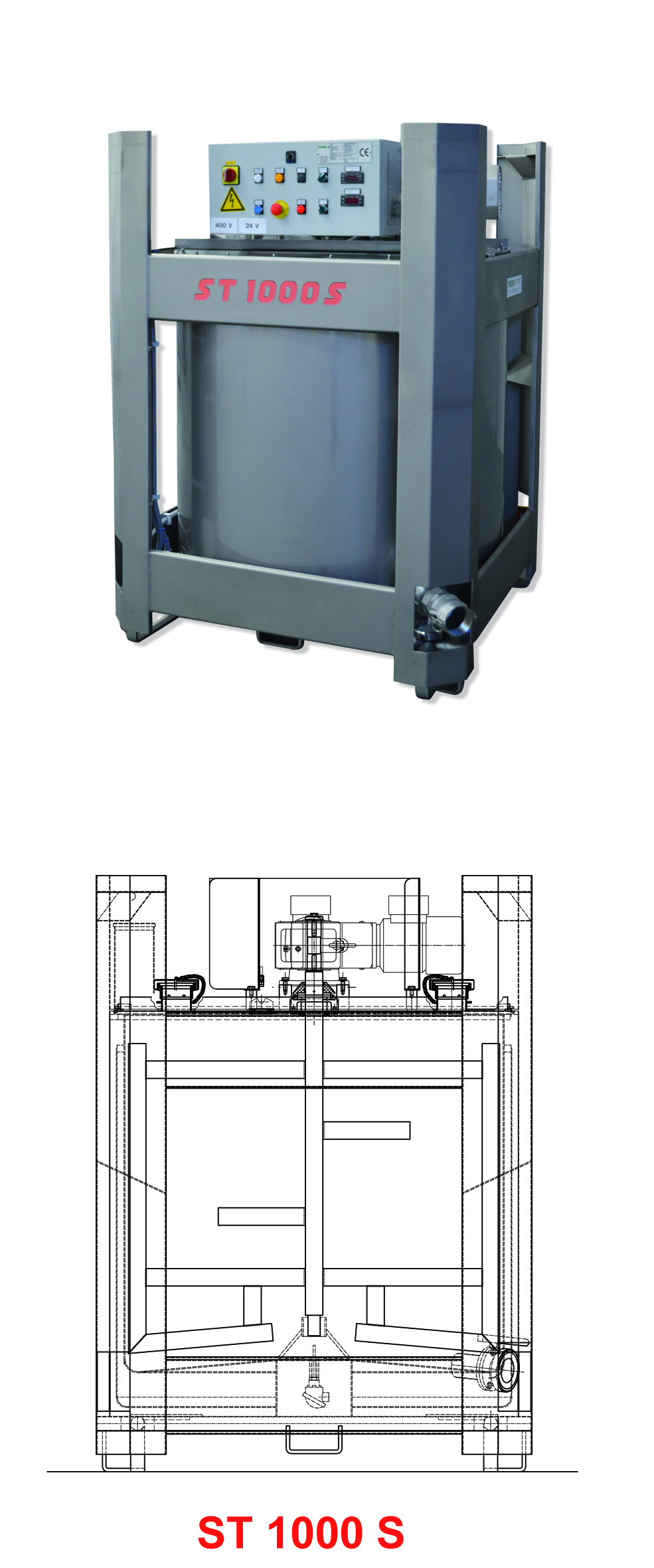

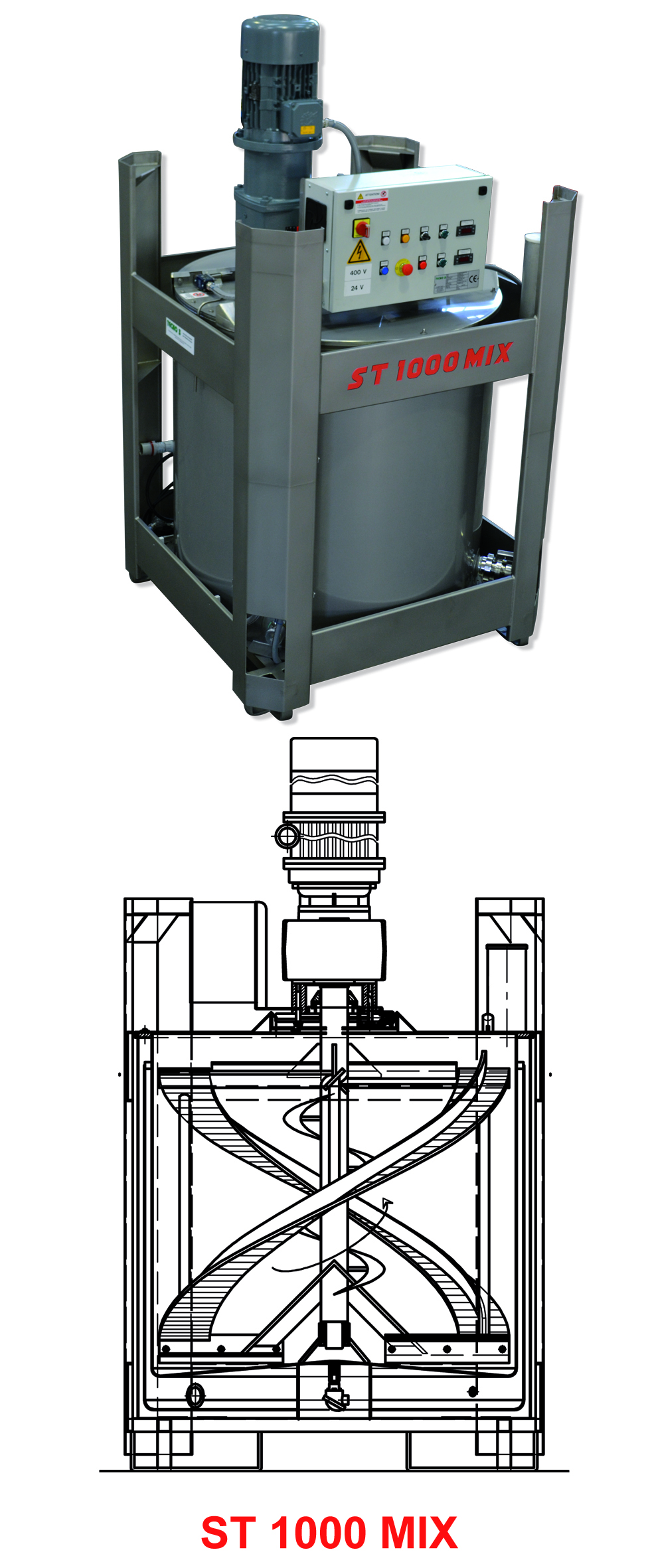

The tanks that make up the series ST1000, ST 1000 S, ST 1000 MIX are made by Tecno 3 for the purpose of achieving the utmost flexibility, compactness and simple operation.Entirely made of AISI 304 stainless steel, they have all the necessary equipment to be autonomous in manufacturing departments. They are all equipped with an independent heating system with open-vessel water. The temperature is set by the operator in relation to the product contained and is controlled by specific temperature regulators located on the control panel. The insulation on the lining and on the bottom considerably reduces heat loss and saves energy. A special perimeter frame, which can be lifted from all 4 sides using a forklift truck or a pallet truck ensuring the maximum protection for the control components, allows them to be moved to the various processing areas.The ST 1000 base model is equipped with an internal stirrer with a special constructive shape that ensures effective and homogeneous mixing. The control panel can be used to set the pause/work time intervals in order to save energy during prolonged storage.We guarantee that there is no contamination between the lubricating oil of the motor reducer (in the event of leaks due to broken seal gaskets) thanks to a special device that conveys the oil the outside the tank. The upper part is equipped with an openable half-lid for manual loading and 2 DN65 inlets. The bottom part, specifically designed to fully unload the product, features two DN65 throttle valves. The special construction of the shape allows two tanks to be placed one on top of the other if they are filled with product, and at least three tanks in case they are empty.In addition to all the positive characteristics described above, the model ST 1000 S offers the possibility to carry out a complete and effective sanitising using aqueous solutions containing specific additives.The entire construction, inside and outside, is implemented with special measures to prevent the product or wash water from stagnating after sanitising.In particular, the internal agitator is fully welded and fitted without any part connected with screws or bolts, grazing the side and bottom surface in order to ensure effective and homogeneous mixing without scraping.The support beam of the motorisation and the half-lids have no sharp edges or points difficult to clean: all the corners are rounded.A special additional seal at the top of the agitation shaft prevents infiltrations of the product and wash water into the movement transmission cavity.The beam and the two DN65 inlets for the product, positioned on the fixed half-lid, are set up to receive the washing device, Series DLT, which can be supplied as a tank accessory.The external structure is built with bends or stiffened parts which allow the wash water to flow out completely.The model ST 1000 MIX was specifically designed and developed in order to achieve fast and homogeneous mixing of different ingredients, fluid with fluid, fluid with the addition of solids (whole nut, grains, etc.), as well as ensuring all the positive qualities of the tanks of the ST1000 range.The mixer has a special double spiral shape, an internal one near the central shaft and an external one near the side surface, to create a very efficient vertical mixing flow. The scrapers on the bottom help the mixing procedure and encourage product discharge.The mixing movement is produced by a motor-reducer with increased power compared to the motors usually installed in the other tanks of the same series, with the possibility to manage, via inverter, the right speed during the mixing phase and the maintenance phase, respectively.In this second stage it is also possible to set the pause/operating times from the control panel, to save energy during prolonged storage.The enhanced handling units prevent overlapping the ST1000MIX tanks.