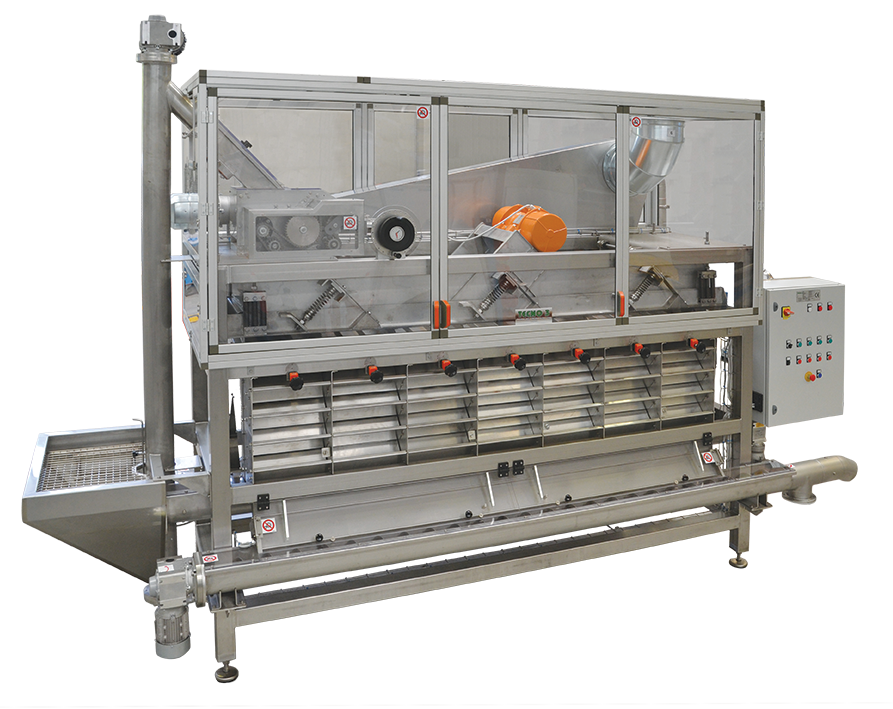

Cocoa winnowing systems

TECNO 3‘s cacao winnowing systems are designed to be compact and ensure an optimal result in terms of separating the nibs from the shells.

They are easy to clean and all the areas where the process takes place can be inspected.

The roasted beans pass through a pair of crushing rollers and the crushed cocoa that is obtained falls on a sifter with chain links of different size in the direction of travel. The nibs move down and form a thin layer thanks to the oscillating horizontal movement of the sifter and a series of rods that move along its surface to prevent fragments of product from piling on top of each other. Each particle goes through the sifter and falls when the size of the mesh matches the size of the particle itself.

At the end of the path, the larger fragments, which are bigger than the maximum mesh size, are redirected with an auger to the initial hopper and passed again through the crushing rollers. Each one of the seven sections of the sifter has a small hopper to collect the sorted particles through a labyrinth-like route. As the particles fall, they go though an upward flow of air that separates the shell, which is lighter, from the cocoa nib, which via an auger is collected and sent to an intermediate storage area or directly to the milling system. On the opposite side of the machine, the shell is sent to a designated container through another auger.

The shell is successfully separated from the nib depending on the regularity of the size of the pieces produced through the crushing rollers and the fine adjustment of the airflows applied to the drop labyrinths.

Entirely made with 304 AISI stainless steel, TECNO 3‘s FRC series winnowing systems are managed by a comprehensive independent electric system in line with current regulations.