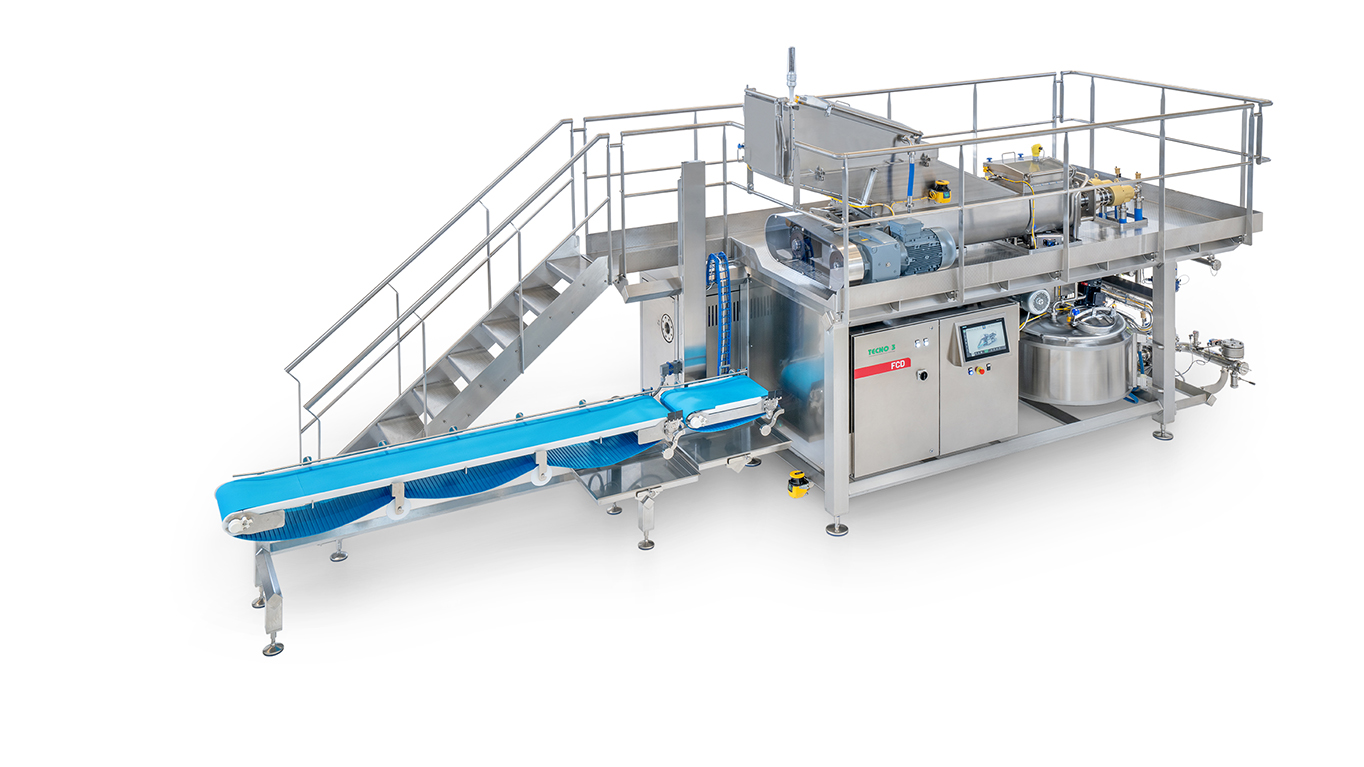

FCD

Continuous melting blocks of cocoa mass and chocolate, blocks of fats, anhydrous and hydrated butter in a single plant and in a small space

INNOVATIVE

EFFICIENT

COMPACT

CLEAN

ROBUST

PRODUCTIVE

FAST

VERSATILE

The innovative design of the FCD series continuous melter allows blocks of cocoa and chocolate mass, blocks of fat, anhydrous butter and hydrated fat (vegetable fat, dairy butter, etc.) to be processed in a single plant and is intended for the confectionery, dairy and food industries.

It is equipped with a special innovative system that guarantees high productivity, reduced energy costs and a saving in labour. The thermal exchange is highly efficient thanks to the mechanical work performed by hot rotors, which carry out a scraping action on the surface of the blocks.

The blocks to be processed are positioned on the cadence belt by the operator either manually or with automatic devices and are continuously conveyed to the feed unit of the loading mouth and conveyed to the heated and thinly spiralled removal and melting rotors. It acts as a scraper and constantly creates a new area to melt in contact with the hot part.

The melting chamber is equipped with an innovative radar device, which constantly measures and manages the level of liquid product inside of the melting room: it allows the complete melting of the solid residues after being passed under the rotors.

The same device also controls the outflow of the product, which, via the outlet located at the lowest part of the chamber, is continuously drawn in and sent to the production processes downstream.

The new FCD Melter can be equipped with automatic devices to completely empty the melting tank and the flow pipes, if you need to change the product.

The melting cycle is considerably reduced without a need for excessively high temperatures, which allows a preservation of the properties of the raw material.

What you can melt

With the FCD series continuous melter it will be possible for the first time to process different types of raw material in one plant

What are the characteristics

Possibility of processing several product types in one plant

Continuous melting cycle with automatic loading possible

Reduced energy consumption

Minimum overall system space

Plant supplied and shipped in a single block, greatly reducing installation time and costs

Innovative product feed and cadence belts that can be removed quickly and without tools for easy cleaning and washing

Combined mechanical and thermal action for optimal melting

Double temperature control circuit integrated in the plant that can be individually set to maintain the quality characteristics of the raw material unchanged

Double filtering system to catch unwanted substances and metal impurities

Product change facilitated by any automatic devices for total emptying

Additional melting unit in addition

The software developed on a PLC allows all the working parameters of the plant to be managed and stored, with the possibility of transferring data to the company network

Innovative washing device using water or grease/oil depending on the product to be processed

Possibility to inspect the plant at all points involved in the production process

Versatility and modularity of the plant, with the possibility of customised configurations according to production requirements

Advanced safety systems with laser markers of risk zones, avoiding light curtains

Managed loading system with block cadencing

Access areas to the upper floor of the plant with non-slip finish walking surface

Level management with radar technology

New operator panel for improved human-machine interaction and easier usability

Integrated predictive maintenance monitoring and reporting system with remote control capability

FCD series continuous melter running

Related products