Continuous melting in small spaces

Efficient

compact

continuous

robust

fast

gentle

The FCS series mobile continuous melter has been specially designed for:

- melting of products with and without inclusions

- melting chocolate chips and solid products for production lines

- continuous recovery of scrap to be reintegrated directly into the production line

- melting of products in rework areas

The machine is completely autonomous, as it is equipped with an electrical panel, management software and a PLC-controlled temperature control system for the water in the cavity.

Its particular delicacy allows the recovery of solid inclusions, keeping them intact.

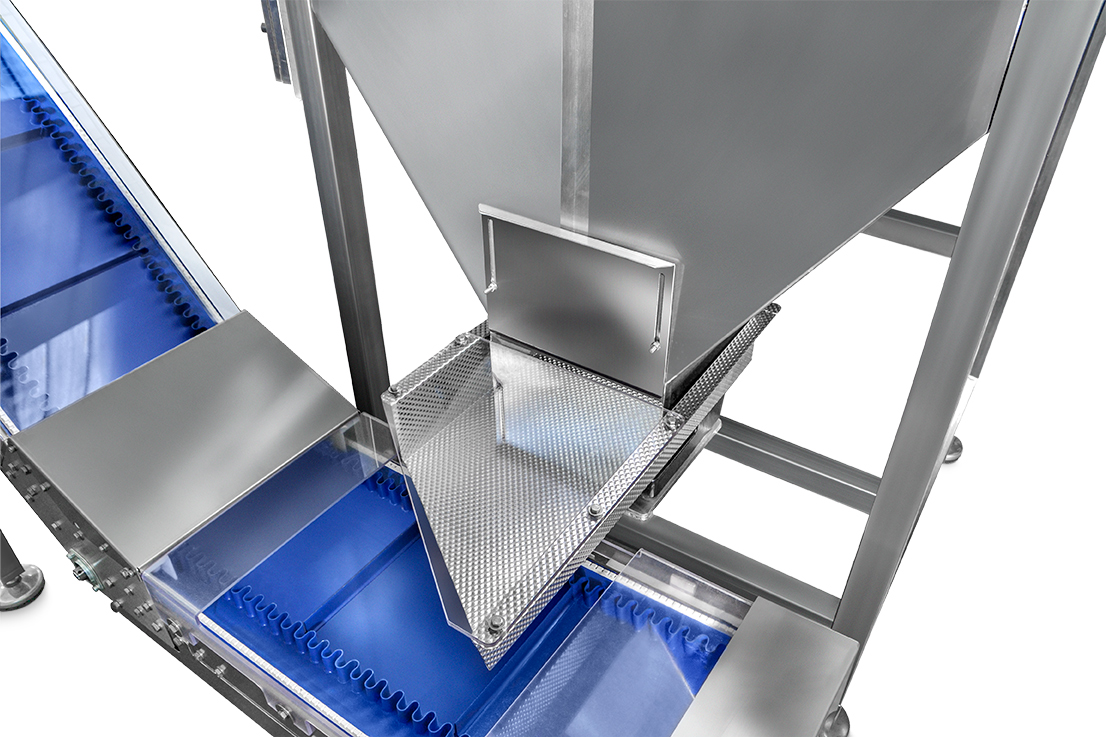

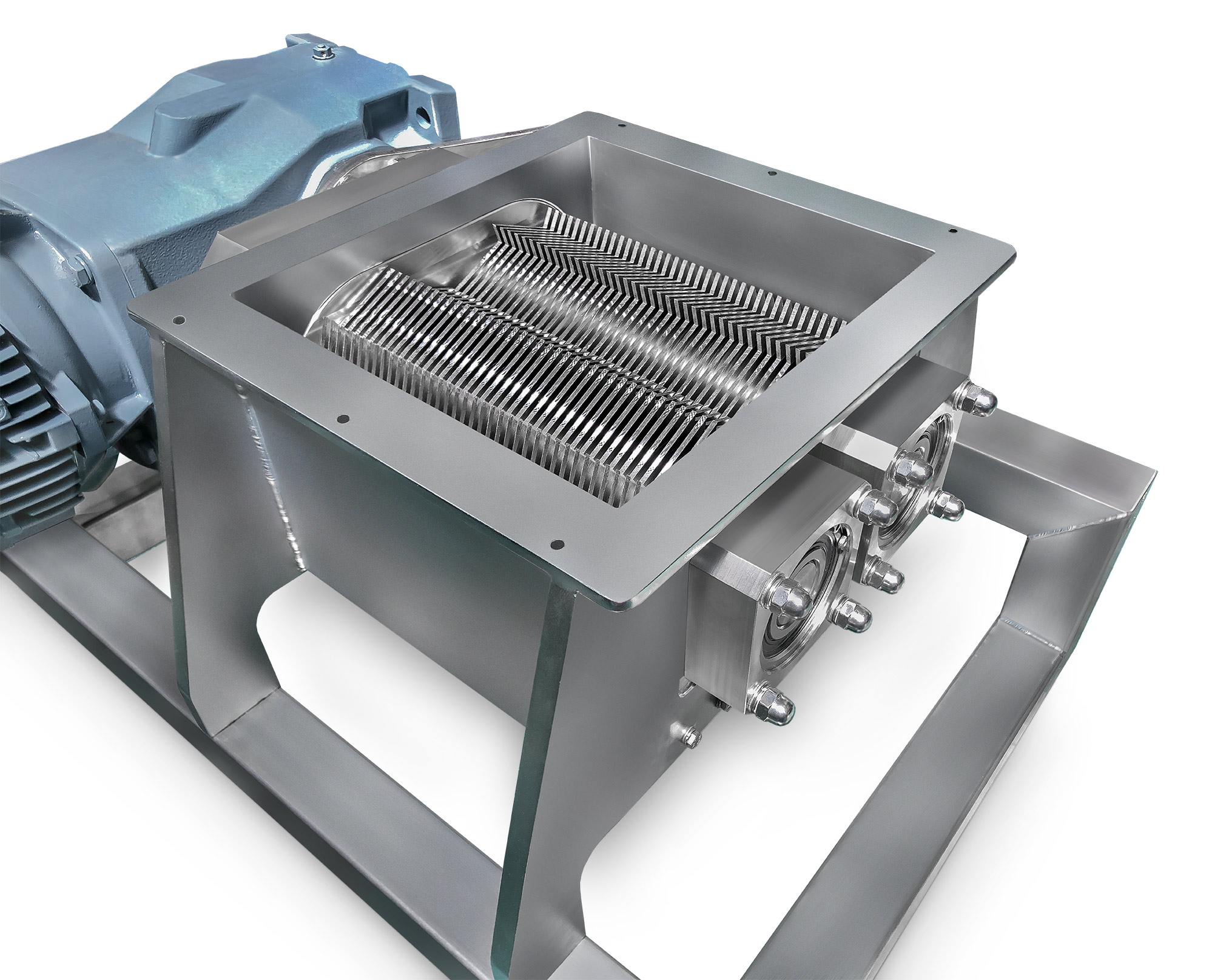

Product loading can be done by the operator manually or automatically by a continuous loading system to dose the right amount of product to the crushing unit which continuously feeds the melting chamber. A heated, parallel-tube heat exchanger rotates inside, configured in such a way as to ensure optimal melting and stirring of the product, while allowing the last solid residues to melt completely.

The chocolate comes out of the melting chamber perfectly fluid and at the correct temperature, is sent to the final filtration unit, prepared for the separation of any inclusions and then destined for further processing according to production requirements.

The small footprint allows the FCS series continuous melter to be positioned even in small spaces.

The machine is designed to completely empty the melting tank and the flow pipes, if you need to change the product.

The FCS series continuous melter is equipped with a dual PLC-controlled temperature control circuit to keep operating temperatures and melt parameters controlled and constant.