Batch ball refining

Efficient

compact

simple

constant

automatic

versatile

The RS1 batch ball refining system has been specially designed to refine fat creams, cream spreads, nut pastes, cocoa mass, compound and chocolate, in full respect of the traditional refining process. It is a system that can be configured for different production capacities and has great production flexibility due to its ability to process different types of products depending on the recipes to be processed in a relatively small working space and with considerable energy savings. Thanks to its ease of use and production versatility, it can process different types of recipes even in small batches.

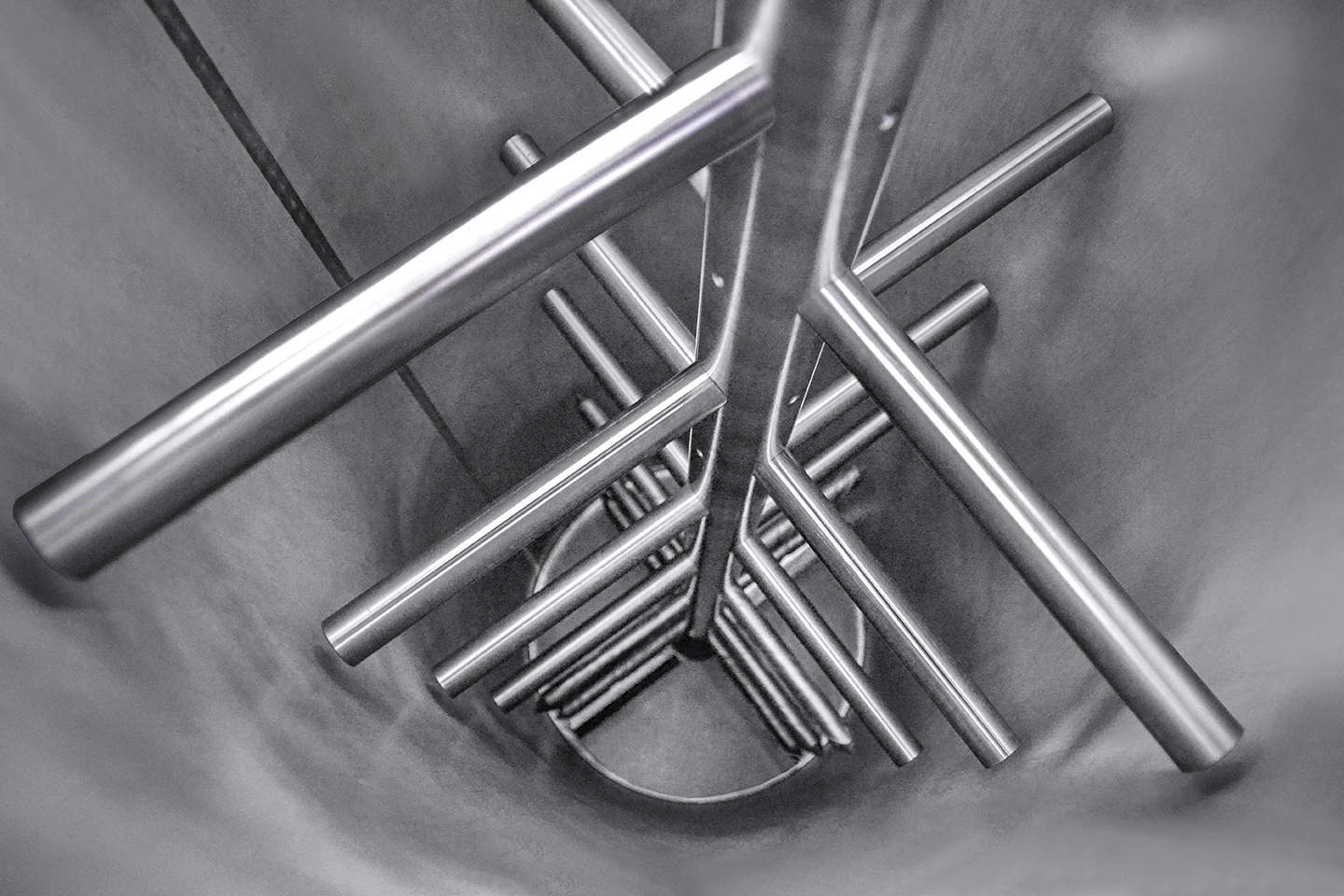

The system consists of a vertical cylinder (refining chamber) in which the balls are placed, set in motion by a reel agitator connected to a gear motor located in the upper area of the mill. For correct operation of the system, the ingredients, adequately dosed, must be added gradually with a logical sequence.

The product recirculates constantly throughout the refining time, from the bottom of the cylinder to the top. The duration of the refining process varies according to the recipe and the fineness desired in the final product. The RS1 series batch ball refining plant is equipped with a fully insulated temperature control circuit to keep the operating temperature controlled and constant. All the process parameters can be set from the operator panel and controlled from the PLC.