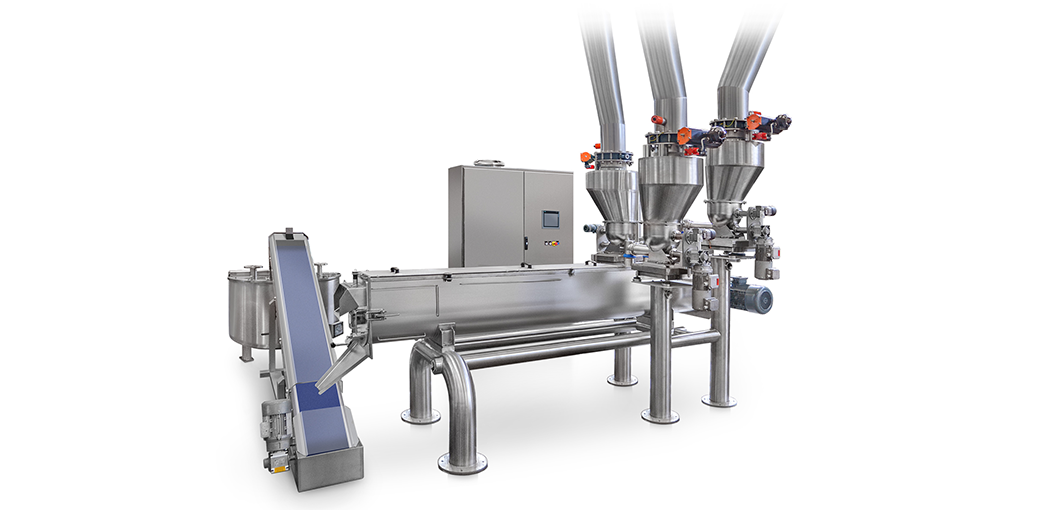

Continuous doser-mixer with conveyor belt

The TECNO 3 continuous doser-mixer mod. MDC is used in the production process of chocolate, creams and semi-finished products for ice-cream and confectionery, to dose and mix recipe liquid and solid ingredients in a constant and homogeneous way.

The ingredients are dosed simultaneously and continuously with great accuracy, according to their physical characteristics, using appropriate systems based on load cells or precision volumetric counters. They enter the rear side of the tank, are deeply mixed and the mixture comes out by overflowing from the front side, to be sent to the next processing step.

The easy disassembly of all parts in contact with the product and the possibility of a thoroughly cleaning and sanitizing make the line extremely flexible for the various applications.

This is one of the company’s most successful systems, subject to continuous upgrades so as to enable complementary operations. For example, the positioning of the tank at head height for easy inspection, the possibility of completely replacing the flavouring unit to avoid pollution, the grains conveying system to the dosing hopper which consists of a slanting belt with flights, easy to be disassembled, removed and sanitised, fed by means of a vibrating plane from a dedicated container.

Recipes can be set and stored on the touch-screen operator panel. Their management and the correct dosing of the ingredients are checked by a PLC, which also manages all the other parameters, such as tank temperature, mixer speed and direction of rotation, product level and all the various related systems.