SIGEP AND PRO SWEETS 2019

TECNO 3 will soon be present at two internationally renowned events to promote its latest generation plants:

SIGEP, the show that will be held from the 19th till the 23rd January ’19 in Rimini.

TECNO 3 will be pleased to welcome you at our booth N. 173 -. B3, to show you the following machines:

The BEAN TO BAR LINE, made up of two compact units performing all the operations required in the technological process, starting from the cocoa bean processing up to the finished chocolate.

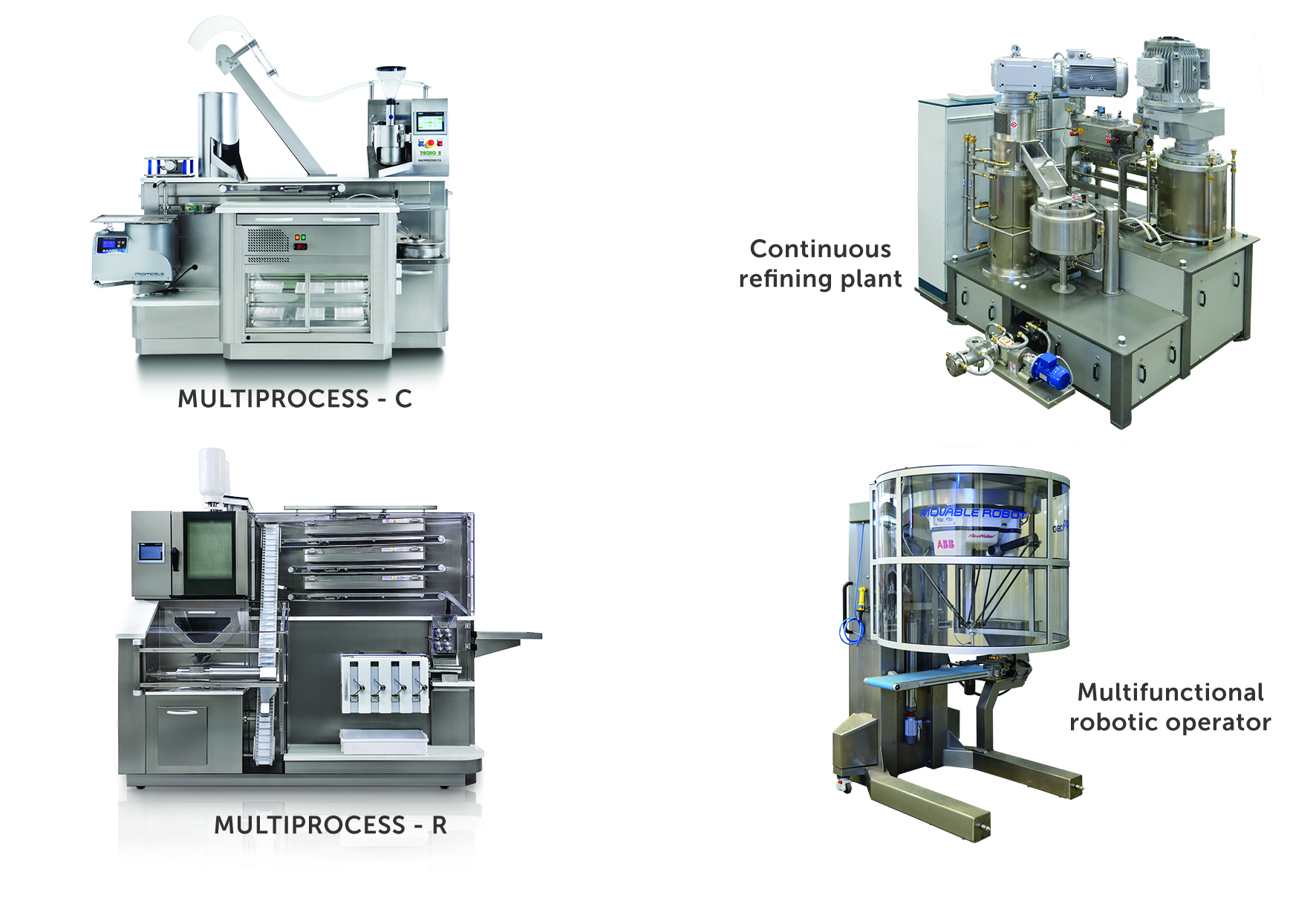

a) Multiprocess R: the 1° unit starts from the coca bean to get the nibs. The process consists is roasting, debacterizing and winnowing, with the separation of the peel from the nibs. The line can also be used with excellent results for nut roasting and debacterizing. All parts are easily and quickly disassemblable for sanitization.

b) Multiprocess C: the 2° unit starts from the cocoa bean up to the chocolate. Processing foresees nibs grinding to get the cocoa mass, then the ingredients mixing, refining and conching. This machine is available in 3 versions, respectively for 5, 25 and 50 Kg. processing capacities. The smallEST version (5 Kg.) also comprises chocolate tempering and depositing into the moulds, moulds shaking and cooling to get the end product. Sanitizing and recipe changeover are enabled thanks to the complete absence of pumps and connection pipes and the easy disassembly of all the machine parts. The system can also be used successfully for the production of paste from nut and lipid-base cream.

PROSWEETS, the show that will be held from the 27th till the 30th January ’19 in Cologne.

TECNO 3 will be pleased to welcome you at our booth N. D078 – E079, to show you the following machines:

The BEAN TO BAR LINE, that is described hereinabove.

The LIPID BASE CREAM LINE: it consists in one vertical heated mixer (mod. ST1000Mix) where all the ingredients for the preparation of the recipe are loaded, a conveyor belt to feed the mixture and a refining unit mod. P10S400, a combination of a two- roll pre-refiner, -a vertical roll refiner, a ball- mill refiner and a vibrating screen.

The machine features special characteristics, such as the excellent compactness with reduced footprint, the continuous processing and a final product with optimal rheological characteristics.

The ORM ROBOTISED STATION, that was born to satisfy the needs of automation and flexibility of the modern production processes. Wheel mounted, it can be easily moved between the different work positions and rapidly connected. The unit is equipped with a multi-camera vision system, that tracks the products at inlet-outlet. Being fully customizable, the vision system can also perform product compliance monitoring (shape, colour, integrity etc.).

TECNO 3 technicians will be pleased to meet you to describe in detail the systems shown in the stands, respond to your requests and you present you the full production range of our company.