PRO SWEETS 2018

TECNO 3 will be present at the PROSWEETS exhibition in Köln (28-31/01/18) with its own booth N. D078 E079, Hall 10.1.

Our technicians and salesmen will be pleased to welcome you at our stand, to show and explain you the new technologies developed in the chocolate field.

The machines exhibited will be the following ones:

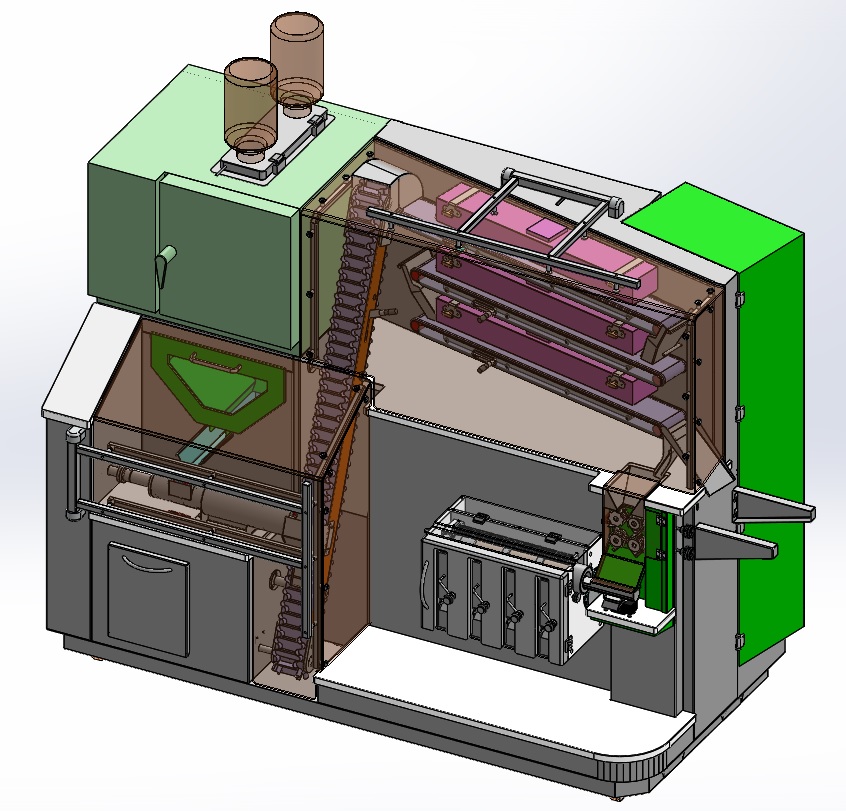

1. BEAN TO BAR LINE: it consists in two compact units carrying out all the operations needed for processing the cocoa bean up to the finished chocolate:

a) Multiprocess R: this first unit starts from the cocoa bean to get the nibs. The process foresees roasting, debacterizing, winnowing with the separation of the peel from the cocoa nibs. The line can be used with excellent results also for nut roasting, peeling and debacterising. Easy cleaning thanks to the quick disassembly of all the parts.

b) Multiprocess C: the 2° unit starts from the cocoa bean up to the chocolate. Processing foresees nibs grinding to get the cocoa mass, then the ingredients mixing, refining and conching. The small version (5 Kg.) also comprises chocolate tempering and depositing into the moulds, moulds shaking and cooling to get the end product. Sanitizing and recipe changeover are enabled thanks to the complete absence of pumps and connection pipes and the easy disassembly of all the machine parts. The system can be also applied to the production of paste from nut and lipid-base cream.

2. MDC: The MDC-A series continuous doser mixer is used in the production of chocolate and creams, to evenly dose and mix the liquid and solid ingredients that are in the recipes. Made entirely in AISI 304 stainless steel, the machine can be used in a line to continuously feed the refining plants or as a self contained unit, to be placed in different positions in the production lines, thanks to its easy movable structure on wheels. The recipe management and the correct dosage of the ingredients, are controlled with PLC, which also manages all the other parameters, such as the tank temperature, the mixer’s speed and the direction of rotation, the product level, etc.. The TECNO 3 continuous doser-mixer makes it possible to manage very small quantities of mixture, a rapid change of recipe and an easy substantial cleaning.

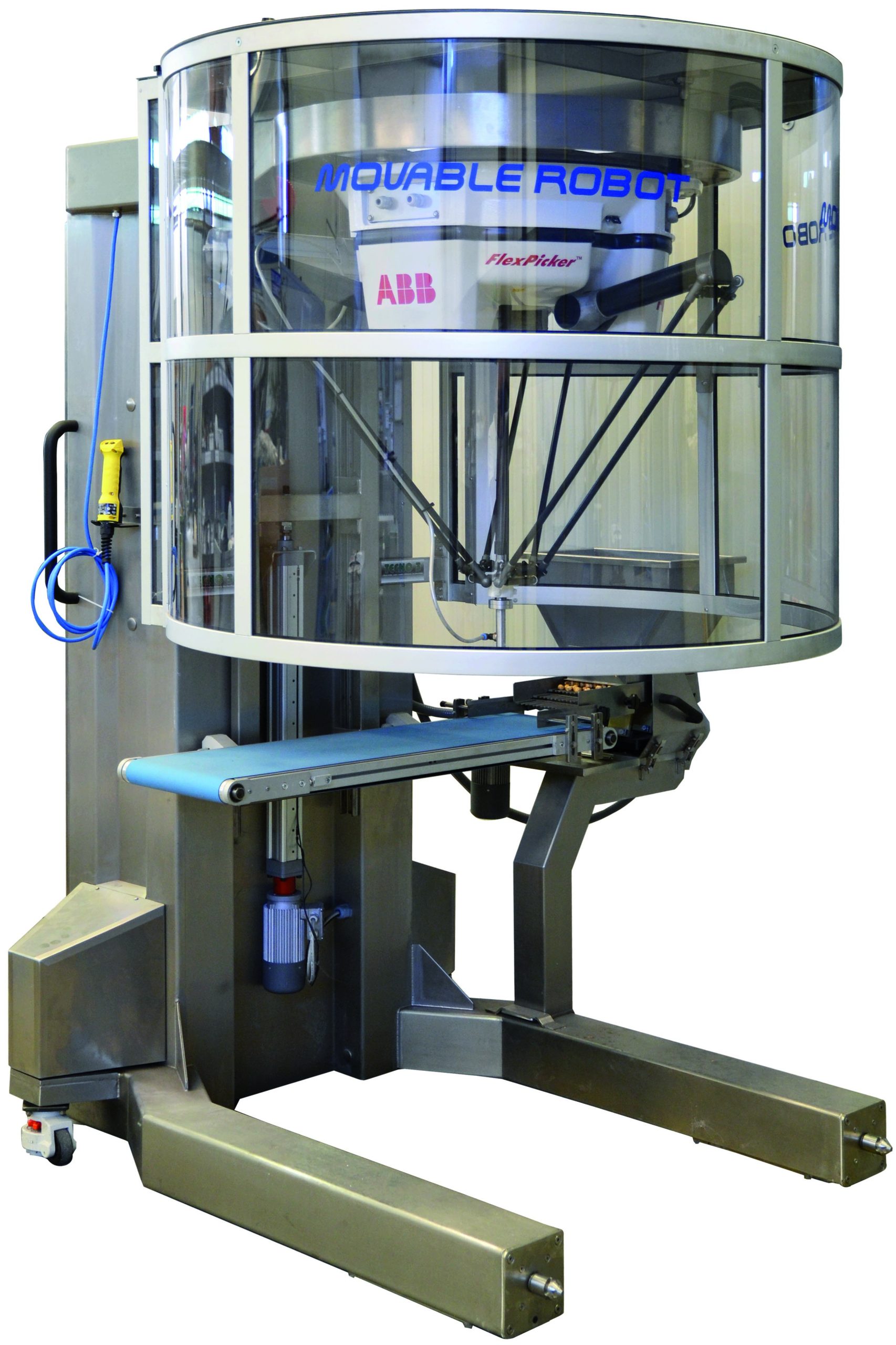

3. ORM: The new ORM robotised station was born in order to satisfy the needs of automation and flexibility of the modern production processes. The innovative column structure upon wheels, makes it easy to move the machine between the different work positions. Once it reaches its destination, the station is secured by means of a suitable mechanism. The connections between the machines and lines to be served are also very quick, as they are carried out by means of industrial modular connectors (power, signals, bus, pneumatics). The accessory devices of the station, such as the belts, the vibrating hoppers, the rotary tables, the loaders or the dispensers are interchangeable depending on the operation to be carried out and are directly hooked to the column. The station is equipped with a multi-camera vision system for tracking products at inlet – outlet. Being fully customizable, the vision system can also perform product compliance monitoring (shape, colour, presence/absence of parts etc.).