CONTINUOUS DOSER MIXERS FOR LIQUID AND SOLID PRODUCTS

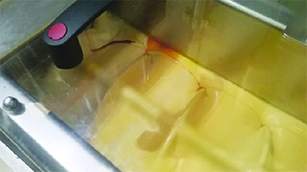

The Tecno 3 MDC-A series continuous doser-mixer is used in the chocolate and cream production process to evenly dose and mix the liquid and solid ingredients required in the recipes.

It may feed refining systems or be installed as a freestanding unit in different points along production lines (e.g. addition of solid fractions or flavourings), as it can be easily transported thanks its wheeled base.

A specifically developed software ensures accurate ingredient dosage, and allows the user to save process data. All other parameters, such as the tank temperature, the mixer’s speed and the direction of rotation, the product level, etc. are controlled via PLC and may be configured from the touch screen.

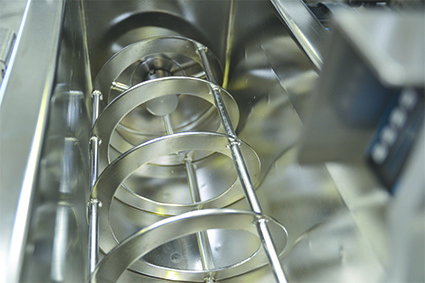

It is possible to combine different interchangeable agitators with various shapes depending on the relevant products, thus ensuring the best mixing results.

The Tecno 3 continuous doser-mixer has compact dimensions and can handle even limited amounts of mixture. Quick recipe change and thorough cleaning are guaranteed thanks to a number of features: the solid ingredient containers are equipped with a quick-release mechanism, the entire flavouring unit may be replaced to avoid contamination, the mixing tank is easy to disassemble and the belt used to convey the product (from the MDC to the point of use) has a cantilever design thanks to which it can be removed laterally.